-

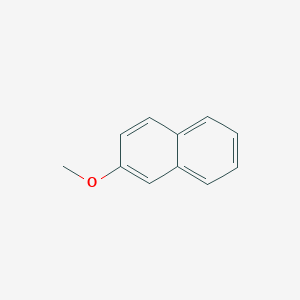

2-甲氧基萘

- names:

Nerolin Yara Yara

- CAS号:

93-04-9

MDL Number: MFCD00004061 - MF(分子式): C10H7OCH3 MW(分子量): 158

- EINECS: Reaxys Number:

- Pubchem ID:7119 Brand:BIOFOUNT

| 货品编码 | 规格 | 纯度 | 价格 (¥) | 现价(¥) | 特价(¥) | 库存描述 | 数量 | 总计 (¥) |

|---|---|---|---|---|---|---|---|---|

| LSH60369-1KG | 1KG | 95% | ¥ 835.00 | ¥ 835.00 | Backorder | ¥ 0.00 |

| 中文别名 | 2-甲氧基萘:(93-04-9) |

| 英文别名 | Nerolin Yara Yara:(93-04-9) |

| CAS号 | 93-04-9 |

| SMILES | COC1=CC2=CC=CC=C2C=C1 |

| Inchi | InChI=1S/C11H10O/c1-12-11-7-6-9-4-2-3-5-10(9)8-11/h2-8H,1H3 |

| InchiKey | No data available |

| 分子式 Formula | C10H7OCH3 |

| 分子量 Molecular Weight | 158 |

| 闪点 FP | No data available |

| 熔点 Melting point | 70-73℃ |

| 沸点 Boiling point | 274.0 °C |

| Polarizability极化度 | No data available |

| 密度 Density | No data available |

| 蒸汽压 Vapor Pressure | No data available |

| 溶解度Solubility | |

| 性状 | DryPowder; Liquid; OtherSolid; PelletsLargeCrystals |

| 储藏条件 Storage conditions | storage at -4℃ (1-2weeks), longer storage period at -20℃ (1-2years) |

1.实验前需戴好防护眼镜,穿戴防护服和口罩,佩戴手套,避免与皮肤接触。

2.实验过程中如遇到有毒或者刺激性物质及有害物质产生,必要时实验操作需要手套箱内完成以免对实验人员造成伤害

3.实验后产生的废弃物需分类存储,并交于专业生物废气物处理公司处理,以免造成环境污染Experimental considerations:

1. Wear protective glasses, protective clothing and masks, gloves, and avoid contact with the skin during the experiment.

2. The waste generated after the experiment needs to be stored separately, and handed over to a professional biological waste gas treatment company to avoid environmental pollution.

| 产品说明 | 2-甲氧基萘:(93-04-9)用于科学研究及合成中间体,93-04-9其他参数见主页 |

| Introduction | Nerolin Yara Yara:(93-04-9)Used in scientific research and synthetic intermediates,93-04-9 other details as description |

| Application1 | |

| Application2 | |

| Application3 |

| 警示图 | |

| 危险性 | warning |

| 危险性警示 | No data available |

| 安全声明 | H303吞入可能有害+H313皮肤接触可能有害+H333吸入可能对身体有害 |

| 安全防护 | P264处理后彻底清洗+P280戴防护手套/穿防护服/戴防护眼罩/戴防护面具+P305如果进入眼睛+P351用水小心冲洗几分钟+P338取出隐形眼镜(如果有)并且易于操作,继续冲洗+P337如果眼睛刺激持续+P313获得医疗建议/护理 |

| 备注 | 实验过程中防止吸入、食入,做好安全防护 |

Ren 化学品安全技术说明书 | 版本:1.0 | |||

按照GB/T16483、GB/T17519编制 | 修订日期:10.07.2019 | |||

打印日期:19.02.2020 | ||||

版权所有:范德(北京)生物科技有限责任公司 | 最初编制日期:25.05.2017 | |||

公司网站:WWW.BIO-FOUNT.COM | SDS编号:BIOFOUNT-HXH505441 | |||

版权所有:BIOFOUNT BEIJING BIO TECH CO.,LTD | 产品编号:BIOFOUNT-HXH505441 | |||

2-甲氧基萘 | ||||

说明书目录 | ||||

第1部分 | 第2部分 | 危险性概述 | ||

第3部分 | 成分/组成信息 | 第4部分 | 急救措施 | |

第5部分 | 消防措施 | 第6部分 | 泄露应急处理 | |

第7部分 | 操作处置与储存 | 第8部分 | 接触控制/个体防护 | |

第9部分 | 理化性质 | 第10部分 | 稳定性和反应性 | |

第11部分 | 毒理学信息 | 第12部分 | 生态学危害信息 | |

第13部分 | 废弃处置 | 第14部分 | 运输信息 | |

第15部分 | 法律法规信息 | 第16部分 | 其他补充信息 | |

第1部分:化学品及企业标识 | ||||

1.1 产品标识 | ||||

2-甲氧基萘 | ||||

ENGLISH NAME: | 2-Methoxynaphthalene | |||

HXH505441 | ||||

BIOFOUNT | ||||

93-04-9 | ||||

1.2 安全技术说明书提供者的详情 | ||||

制造商或供应商名称: | ||||

制造地址: | 59 KANGTAI AVENUE BINHAI NEW DISTRICT TIANJIN 300450 TIANJIN CHINA 范德(天津)生物科技有限责任公司 天津市滨海新区康泰大道59号九州通绿谷健康产业园 邮政编码:300450 | |||

电话号码: | ||||

1.3 应急咨询电话 | ||||

紧急联系电话: | ||||

1.4 物质或混合物的推荐用途和限制用途 | ||||

已确认的各用途: | 仅用于科学研发,不作为药品、家庭或其它用途。 | |||

第2部分:危险性概述 | ||||

2.1 GHS危险性类别 | ||||

暂无数据 | ||||

2.2 GHS 标签要素,包括防范说明 | ||||

象形图 | ||||

暂无数据 | ||||

暂无数据 | ||||

H401 | ||||

警告申明 | ||||

暂无数据 | ||||

P273+P501 | ||||

事故响应 | ||||

1.化学品使用过程中,当出现事故或者有紧急情况发生时,当事人应第一时间向应急小组负责人汇报后,由应急小组采取措施防止事态扩大。2.应急小组对受害人采取救护措施。 | ||||

暂无数据 | ||||

废弃处置 | ||||

暂无数据 | ||||

2.3 物理和化学危险 | ||||

暂无数据 | ||||

2.4 健康危害 | ||||

H401 | ||||

2.5 环境危害 | ||||

暂无数据 | ||||

2.6 其它危害物 | ||||

暂无数据 | ||||

第3部分:成分/组成信息 | ||||

物质/混合物 | 物质 | |||

3.1 物 质 | ||||

C11H10O | ||||

158.2 | ||||

93-04-9 | ||||

EC-编号 | 暂无数据 | |||

根据相应法规,无需披露具体组份。 | ||||

第4部分:急救措施 | ||||

4.1 必要的急救措施描述 | ||||

吸入 | ||||

立即将患者移至空气新鲜处,发现呼吸困难时,必须立即采取吸氧处理,停止呼吸时采取人工呼吸。同时联系及时就医。 | ||||

皮肤接触 | ||||

立即脱去或者剪去污染的衣物,迅速用大量的流动清水冲10-20分钟甚至更长时间后,赴医院就医。 | ||||

眼睛接触 | ||||

立即用大量的流动清水冲10-20分钟后赴医院就医处理。 | ||||

食入 | ||||

误食化学物品后,应立即采取措施进行催吐。1.若误食化学品呈酸性,则可服用大量牛奶和水,促使食如折呕吐。2.若误食化学品呈碱性,则可服用大量牛奶、清水和醋,促使其呕吐,紧急处理后,应及时送至医院进行治疗(仅供参考)。食如者昏迷状态下禁止催吐,以免造成窒息。 | ||||

4.2 最重要的症状和健康影响 | ||||

最重要的已知症状及作用已在标签(参见章节2.2)和/或章节11中介绍 | ||||

暂无数据 | ||||

4.4 对医生的特别提示 | ||||

暂无数据 | ||||

第5部分:消防措施 | ||||

5.1 灭火介质 | ||||

采用泡沫灭火器、二氧化碳灭火器,避免造成二次污染发生。 | ||||

5.2 源于此物质或混合物的特别的危害 | ||||

暂无数据 | ||||

5.3 灭火注意事项及保护措施 | ||||

小规模着火需戴好口罩,防止有毒气体吸入。火灾发生时及时启动应急相应系统撤离至上风口处,并联系当地消防部门灭火。 | ||||

第6部分:泄露应急处理 | ||||

1.泄露后首先启动应急相应系统2.泄露处理前,需穿戴好安全安全防护鞋、穿戴好安全防护手套(强酸性物质需穿戴防酸碱手套)、根据吸入危险性穿戴相应防护面罩。 有关个人防护,请看第8部分。 | ||||

6.2 环境保护措施 | ||||

参照《范德生物化学废弃物处理方法》处理,防止对环境造成危害,处理后交由有资质的废弃物处理结构进行处理,以免造成环境污染。 | ||||

参照《范德生物化学品废弃物处理方法》对泄露的化学品进行处理,处理前需用化学品吸附岩棉对泄露区域进行围挡,形成“围堰”防止泄露扩大。 | ||||

6.4 参考其他部分 | ||||

丢弃处理请参阅第13节。 | ||||

第7部分:操作处置与储存 | ||||

7.1 安全操作的注意事项 | ||||

使用过程请穿戴好口罩,手套等防护用品,避免与皮肤接触、吸入、误食危险。 有关预防措施,请参见章节2.2。 | ||||

7.2 安全储存的条件,包括任何不兼容性 | ||||

暂时无法提供详细数据,尽可能避免与其他化合物混合存储,避光、通风处存储。 | ||||

第8部分:接触控制/个体防护 | ||||

8.1 控制参数 | ||||

暂无数据 | ||||

8.2 暴露控制 | ||||

适当的技术控制 | ||||

暂无数据 | ||||

个体防护装备 | ||||

一般情况下穿戴安全防护眼镜即可,如有飞溅液体、粉末产生时,请佩戴防溅面罩进行防护。穿戴的防护用品需取得如:GB、NIOSH (美国) 或 EN 166(欧盟) 等相关认证。 | ||||

手套脱去注意事项:手套在使用前必须进行检查,请使用正确的方法脱除手套(不接触手套外部表面),避免身体任何皮肤部位接触到此产品。根据相关法律法规和实验室管理规范制度,手套使用过后,请将被污染的手套谨慎处理,工作后清洗并吹干双手。 所选择的保护手套必须符合法规《劳动防护用品配备标准》、(EU)2016/425以及从此类法规衍生出来的EN 374标准规范。 完全接触保护要求: 手套材料:丁腈橡胶 手套最小的层厚度:0.11 MM 手套溶剂渗透时间:480 分钟 飞溅保护要求: 材料:丁腈橡胶 最小的层厚度 0.11 MM 溶剂渗透时间:480 分钟 如果以溶剂形式应用或与其它物质混合应用,或在不同于《劳动防护用品配备标准》,EN 374规定的条件下应用,请与EC批准的手套的供应商联系。该条只是作为推荐性建议,如遇特殊情况,务必请熟悉该产品属性的专家,选取相关防护用品。此条建议不应该被认定为适应所有特殊条件防护,请根据所处工作条件请求专业工程师指导采取相应防护措施。 | ||||

选择身体部分的防护措施,需要根据危险物质的类型、浓度、量以及特定的工作环境。身体部分防护设备、防护服的类型,必须根据使用者工作场所中的危险物质的浓度、数量进行选择。 | ||||

一般情况下穿戴普通的医用口罩保护呼吸系统即可。有酸雾产生式活性炭类口罩起不到防护作用,如需对粉尘造成损害进行防护时,请采用N95型(US)或P1型(EN 143)类口罩或者防尘面具。特殊情况下使用自吸式呼吸器时,使用的呼吸器必须对呼吸器密闭性、空气供应系统、供气压进行测试,当然呼吸器需通过强制认证标准如:GB、NIOSH(US)、CEN(EU)。 | ||||

环境暴露的控制 | ||||

不要让产品进入下水道。 | ||||

第9部分:理化特性 | ||||

9.1 基本的理化特性的信息 | ||||

形状:暂无数据 | ||||

颜色:暂无数据 | ||||

气味 | 暂无数据 | |||

气味阈值 | 暂无数据 | |||

暂无数据 | ||||

72.0 to 76.0 deg-C | ||||

初沸点和沸程 | 272.0±0.0 °C at 760 mmHg | |||

闪点 | 102.3±8.0 °C | |||

蒸发速率 | 暂无数据 | |||

易燃性(固体,气体) | 暂无数据 | |||

高的/低的燃烧性或爆炸性限度 | 暂无数据 | |||

蒸气压 | 0.0±0.5 mmHg at 25°C | |||

蒸气焓 | 暂无数据 | |||

密度/相对密度 | 1.1±0.1 g/cm3 | |||

.; Stable. Combustible. Incompatible with strong oxidizing agents.Indofine[CS-674] | ||||

正辛醇/水分配系数 | Log POW:3.36 | |||

正辛醇空气分配系数 | Log Kow used: 3.47 (exp database)

Log Kaw used: -2.896 (HenryWin est)

Log Koa (KOAWIN v1.10 estimate): 6.366

Log Koa (experimental database): None/ | |||

自燃温度 | 暂无数据 | |||

分解温度 | 暂无数据 | |||

黏度 | 暂无数据 | |||

暂无数据 | ||||

氧化性 | 暂无数据 | |||

根据碎片估算水溶胶 | WatSol(v1.01est)=22.606mg/L | |||

亨利定律常数(25摄氏度) | Bond Method : 3.11E-005 atm-m3/mole

Group Method: 3.01E-004 atm-m3/mole

Henrys LC [VP/WSol estimate using EPI values]: 7.324E-006 atm-m3/mole/ | |||

9.2 其他安全信息 | ||||

暂无数据 | ||||

第10部分:稳定性和反应性 | ||||

10.1 稳定性 | ||||

暂无数据 | ||||

10.2 危险反应 | ||||

暂无数据 | ||||

10.3 应避免的条件 | ||||

暂无数据 | ||||

10.4 禁配物 | ||||

强氧化剂 | ||||

10.5 危险的分解产物 | ||||

暂无数据 | ||||

第11部分:毒理学信息 | ||||

11.1 毒理学影响信息 | ||||

暂无数据 | ||||

皮肤腐蚀/刺激 | ||||

暂无数据 | ||||

暂无数据 | ||||

呼吸或皮肤过敏 | ||||

暂无数据 | ||||

暂无数据 | ||||

暂无数据 | ||||

生殖毒性 | ||||

暂无数据 | ||||

特异性靶器官系统毒性(一次接触) | ||||

暂无数据 | ||||

特异性靶器官系统毒性(反复接触) | ||||

暂无数据 | ||||

吸入危害 | ||||

暂无数据 | ||||

附加说明 | ||||

暂无数据 | ||||

第12部分:生态学危害信息 | ||||

12.1 生态毒性 | ||||

暂无数据 | ||||

12.2 持久性和降解性 | ||||

暂无数据 | ||||

12.3 快速生物降解的可能性 | ||||

Biowin1 (Linear Model) : 0.8041

Biowin2 (Non-Linear Model) : 0.9530 | ||||

12.4 专家调查生物降解结果 | ||||

Biowin3 (Ultimate Survey Model): 2.7914 (weeks )

Biowin4 (Primary Survey Model) : 3.6966 (days-weeks ) | ||||

12.5 MITI生物降解的可能性 | ||||

Biowin5 (MITI Linear Model) : 0.4947

Biowin6 (MITI Non-Linear Model): 0.5354 | ||||

12.6 厌氧生物降解的可能性 | ||||

Biowin7 (Anaerobic Linear Model): 0.2665 | ||||

12.7 现成的生物降解性预测 | ||||

NO | ||||

12.8 碳氢化合物生物降解 | ||||

Structure incompatible with current estimation method!/ | ||||

12.9 对气溶胶的吸附 | ||||

Vapor pressure (liquid/subcooled): 1.02 Pa (0.00767 mm Hg)

Log Koa (Koawin est ): 6.366

Kp (particle/gas partition coef. (m3/ug)):

Mackay model : 2.93E-006

Octanol/air (Koa) model: 5.7E-007

Fraction sorbed to airborne particulates (phi):

Junge-Pankow model : 0.000106

Mackay model : 0.000235

Octanol/air (Koa) model: 4.56E-005 / | ||||

12.10 羟基自由基反应 | ||||

OVERALL OH Rate Constant = 200.8296 E-12 cm3/molecule-sec

Half-Life = 0.053 Days (12-hr day; 1.5E6 OH/cm3)

Half-Life = 0.639 Hrs | ||||

12.11 臭氧反应 | ||||

No Ozone Reaction Estimation | ||||

12.12 空气中颗粒物吸附的分数(PHI) | ||||

0.00017 (Junge,Mackay)

Note: the sorbed fraction may be resistant to atmospheric oxidation/ | ||||

12.13 土壤吸附系数 | ||||

Koc : 1308

Log Koc: 3.117 / | ||||

12.14 碱/酸催化水解(25℃) | ||||

Rate constants can NOT be estimated for this structure!/ | ||||

12.15 利用对数KOW估算生物累积量 | ||||

Log BCF from regression-based method = 1.972 (BCF = 93.73)

log Kow used: 3.47 (expkow database)/ | ||||

12.16 废水处理中的去除 | ||||

Total removal: 22.53 percent

Total biodegradation: 0.16 percent

Total sludge adsorption: 11.49 percent

Total to Air: 10.88 percent

(using 10000 hr Bio P,A,S)/ | ||||

12.17 三级逸度模型 | ||||

Mass Amount Half-Life Emissions

(percent) (hr) (kg/hr)

Air 0.201 1.28 1000

Water 19 360 1000

Soil 80 720 1000

Sediment 0.793 3.24e+003 0

Persistence Time: 411 hr// | ||||

12.18 土壤中的迁移性 | ||||

暂无数据 | ||||

12.19 PBT和VPVB的结果评价 | ||||

暂无数据 | ||||

12.20 其他环境有害作用 | ||||

暂无数据 | ||||

第13部分:废弃处置 | ||||

13.1 废物处理 | ||||

None | ||||

None | ||||

第14部分:运输信息 | ||||

14.1 联合国编号 / UN NUMBER | ||||

欧洲陆运危规 / ER/RID: | None | |||

国际海运危规 / IMDG: | None | |||

国际空运危规 / IATA-DGR: | None | |||

14.2 联合国运输名称 / UN PROPER SHIPPING NAME | ||||

欧洲陆运危规: | None | |||

国际海运危规: | None | |||

国际空运危规: | None | |||

欧洲陆运危规 / ER/RID: | None | |||

国际海运危规 / IMDG: | None | |||

国际空运危规 / IATA-DGR: | None | |||

欧洲陆运危规 / ER/RID : | None | |||

国际海运危规 / IM0DG: | None | |||

国际空运危规 / IATA-DGR: | None | |||

None | ||||

14.6 特殊防范措施 / SPECIAL PRECAUTIONS FOR USER | ||||

None | ||||

None | ||||

第15部分:法律法规信息 | ||||

适用法规 | ||||

《中华人民共和国安全生产法》、《职业病防治法》、《化学化工实验室安全管理规范》 | ||||

其它的规定 | ||||

《生产安全事故报告和调查处理条例》、《职业病防治法》、《职业安全和卫生法》美国1970 | ||||

第16部分:其他补充信息 | ||||

其他信息 版权所有:BIOFOUNT BEIJING BIO TECH CO.,LTD 公司。许可无限制纸张拷贝,仅限于内部使用。 上述信息视为正确,但不包含所有的信息,仅作为指引使用。本文件中的信息是基于我们目前所知,就正确的安全提示来说适用于本品。该信息不代表对此产品性质的保证。BIOFOUNT公司及其附属公司对任何操作或者接触上述产品而引起的损害不负有任何责任。更多使用条款,参见发票或包装条的反面。 更多销售条款及条件请参见HTTP://WWW.BIO-FOUNT.COM/或发票或装箱单的背面。欲悉详情,请联系:SALES@BIO-FOUNT.COM | ||||

Chemical safety technical specification | Edition:1.0 | |||||

Prepared according to GB/T16483、GB/T17519 | Revision date:10.07.2019 | |||||

Date of printing:19.02.2020 | ||||||

Date of initial preparation:25.05.2017 | ||||||

WEB:www.bio-fount.com | SDS number:BIOFOUNT-HXH505441 | |||||

Copyright: BIOFOUNT BEIJING BIO TECH CO.,LTD | Product number:BIOFOUNT-HXH505441 | |||||

2-Methoxynaphthalene | ||||||

List of instructions | ||||||

Part 1 | chemicals and enterprise logo | Part 2 | risk overview | |||

Part 3 | Composition / composition information | Part 4 | first aid measures | |||

Part 5 | fire fighting measures | Part 6 | Leakage Emergency Treatment | |||

Part 7 | handling and storage | Part 8 | exposure control / personal protection | |||

Part 9 | physical and chemical properties | Part 10 | stability and reactivity | |||

Part 11 | toxicological information | Part 12 | ecological hazard information | |||

Part 13 | waste disposal | Part 14 | Transport Information | |||

Part 15 | information on laws and regulations | Part 16 | other supplementary information | |||

Part 1: chemicals and enterprise logo | ||||||

1.1 product identification | ||||||

Product Name: | 2-Methoxynaphthalene | |||||

English Name: | 2-Methoxynaphthalene | |||||

Product No.: | HXH505441 | |||||

Brand: | BIOFOUNT | |||||

(CAS No.): | 93-04-9 | |||||

1.2 details of suppliers of safety technical specifications | ||||||

Name of manufacturer or supplier: | BIOFOUNT BEIJING BIO-TECH CO.,LTD | |||||

Manufacturing address: | 59 Kangtai Avenue Binhai New District Tianjin 300450 TIANJIN CHINA BIOFOUNT (Tianjin) Biotechnology Co., Ltd Jiuzhou tonglvgu Health Industrial Park, No. 59, Kangtai Avenue, Binhai New Area, Tianjin Post code: 300450 | |||||

Phone number: | ||||||

1.3 emergency consultation telephone | ||||||

Emergency contact number: | ||||||

1.4 recommended and restricted uses of the substance or mixture | ||||||

Identified uses: | It is only used for scientific research and development, not for medicine, family or other purposes. | |||||

Part 2: risk overview | ||||||

No data available | ||||||

2.2 GHS labeling elements, including precautionary statements | ||||||

Pictogram | ||||||

No data available | ||||||

Signal word | ||||||

No data available | ||||||

H401 | ||||||

Warning statement | ||||||

No data available | ||||||

preventive measure | ||||||

P273+P501 | ||||||

1. In case of accident or emergency during the use of chemicals, the party concerned shall report to the person in charge of the emergency response team as soon as possible, and the emergency response team shall take measures to prevent the situation from expanding. 3. The emergency team shall take rescue measures for the victims. | ||||||

Storage | ||||||

No data available | ||||||

Waste disposal | ||||||

No data available | ||||||

2.3 physical and chemical hazards | ||||||

No data available | ||||||

2.4 health hazards | ||||||

H401 | ||||||

2.5 environmental hazards | ||||||

No data available | ||||||

2.6 other hazards | ||||||

No data available | ||||||

Part 3: Composition / composition information | ||||||

Substance / mixture | material | |||||

3.1 substances | ||||||

Molecular formula | C11H10O | |||||

molecular weight | 158.2 | |||||

(CAS No.) | 93-04-9 | |||||

EC- number | No data available | |||||

According to the corresponding regulations, there is no need to disclose specific components. | ||||||

Part 4: first aid measures | ||||||

4.1 description of necessary first aid measures inhalation | ||||||

inhalation | ||||||

Inhalation: Immediately leave the contaminated area; take deep breaths of fresh air. If symptoms (such as wheezing, coughing, shortness of breath, or burning in the mouth, throat, or chest) develop, call a physician and be prepared to transport the victim to a hospital. Provide proper respiratory protection to rescuers entering an unknown atmosphere. Whenever possible, Self-Contained Breathing Apparatus (SCBA) should be used; if not available, use a level of protection greater than or equal to that advised under Protective Clothing. | ||||||

Skin contact | ||||||

Skin:Immediately flood affected skin with water while removing and isolating all contaminated clothing. Gently wash all affected skin areas thoroughly with soap and water. If symptoms such as redness or irritation develop, Immediately call a physician and be prepared to transport the victim to a hospital for treatment. | ||||||

Eye contact | ||||||

eyes: First check the victim for contact lenses and remove if present. Flush victim's eyes with water or normal saline solution for 20 to 30 minutes while simultaneously calling a hospital or poison control center. Do not put any ointments, oils, or medication in the victim's eyes without specific instructions from a physician. Immediately transport the victim after flushing eyes to a hospital even if no symptoms (such as redness or irritation) develop. | ||||||

Ingestion | ||||||

Ingestion: Do not induce vomiting,If the victim is conscious and not convulsing, give 1 or 2 glasses of water to dilute the chemical and Immediately call a hospital or poison control center. Be prepared to transport the victim to a hospital if advised by a physician. If the victim is convulsing or unconscious, do not give anything by mouth, ensure that the victim's airway is open and lay the victim on his/her side with the head lower than the body. DO NOT Induce vomiting.Immediately transport the victim to a hospital. | ||||||

4.2 most important symptoms and health effects | ||||||

The most important known symptoms and effects are described in the label (see Chapter 2.2) and / or Chapter 11 | ||||||

4.3 instructions and instructions for timely medical treatment and special treatment required | ||||||

No data available | ||||||

4.4 special tips for doctors | ||||||

No data available | ||||||

Part 5: fire fighting measures | ||||||

5.1 extinguishing media | ||||||

Fire extinguishing method and agent | ||||||

Fires involving this compound should be controlled using a dry chemical, carbon dioxide, foam or Halon extinguisher. | ||||||

5.2 special hazards from this substance or mixture | ||||||

No data available | ||||||

5.3 precautions and protection measures for fire fighting | ||||||

In case of small-scale fire, masks shall be worn to prevent the inhalation of toxic gas. In case of fire, the emergency response system shall be started in time to evacuate to the upper air outlet, and the local fire department shall be contacted to put out the fire. | ||||||

Part 6: Leakage Emergency Treatment | ||||||

6.1 personnel protection measures, protective equipment and emergency disposal procedures | ||||||

1. Start the emergency response system first after leakage. 2. Before leakage treatment, wear safety protection shoes, safety protection gloves (anti acid and alkali gloves are required for strong acid substances), and wear corresponding protective masks according to the inhalation risk. For personal protection, see Part 8. | ||||||

6.2 environmental protection measures | ||||||

Refer to the treatment method of Fande biochemical waste to prevent harm to the environment. After treatment, the waste shall be treated by a qualified waste treatment structure to avoid environmental pollution. | ||||||

6.3 storage, removal methods and disposal materials of leaked chemicals | ||||||

The leaked chemicals shall be treated according to the treatment method of Fande biological chemical waste. Before treatment, the leaking area shall be enclosed with chemical absorbent rock wool to form a "cofferdam" to prevent the leakage from expanding. | ||||||

6.4 reference to other parts | ||||||

See section 13 for disposal. | ||||||

Part 7: handling and storage | ||||||

7.1 precautions for safe operation | ||||||

Please wear masks, gloves and other protective articles during use to avoid contact with skin, inhalation and accidental ingestion. See Section 2.2 for precautions. | ||||||

7.2 conditions for safe storage, including any incompatibility | ||||||

It is unable to provide detailed data for the time being. Try to avoid mixed storage with other compounds and storage in dark and ventilated places. | ||||||

Part 8: exposure control / personal protection | ||||||

8.1 control parameters | ||||||

Hazard composition and occupational exposure limit | ||||||

No data available | ||||||

8.2 exposure control | ||||||

Appropriate technical controls | ||||||

No data available | ||||||

Personal protective equipment | ||||||

Eye protection Please use equipment tested and approved by official standards such as NIOSH (USA) or en 166 (EU) for eye protection. | ||||||

Skin protection Take out by hand: gloves must be inspected before use. Please use proper methods to remove the gloves (do not touch the outer surface of the gloves), and avoid any skin parts contacting the product. After use, please handle the contaminated gloves carefully according to relevant laws and regulations and effective laboratory rules and procedures. Please wash and dry your hands. The selected protective gloves must meet the specifications given in regulation (EU) 2016 / 425 and the en 374 standard derived from it. Full contact Material: NBR Minimum layer thickness 0.11 mm Solvent penetration time: 480 minutes Splash protection Material: NBR Minimum layer thickness 0.11 mm Solvent penetration time: 480 minutes If applied in solvent form or mixed with other substances, or under conditions different from those specified in en 374, please contact the supplier of gloves approved by EC. This recommendation is only suggestive and must be evaluated and confirmed by an industrial hygiene expert familiar with the specific situation our customer plans to use. This should not be interpreted as providing approval for any particular usage method. | ||||||

Body protection Choose physical protection measures according to the type, concentration and quantity of hazardous substances and specific workplace. The type of protective equipment must be selected according to the concentration and quantity of hazardous substances in the specific workplace. | ||||||

respiratory system protection There is no need to protect breathing. To protect against dust damage, use N95 (US) or P1 (EN 143) dust masks. Respirators use respirators and parts that have been tested and passed government standards such as NIOSH (US) or cen (EU). | ||||||

Control of environmental exposure | ||||||

Do not let the product into the sewer. | ||||||

Part 9: physical and chemical properties | ||||||

9.1 information on basic physical and chemical properties | ||||||

Appearance and character | shape:No data available | |||||

colour:No data available | ||||||

smell | No data available | |||||

Odor threshold | No data available | |||||

PH value | No data available | |||||

Melting point / freezing point | 72.0 to 76.0 deg-C | |||||

Initial boiling point and boiling range | 272.0±0.0 °C at 760 mmHg | |||||

flash point | 102.3±8.0 °C | |||||

Evaporation rate | No data available | |||||

Flammability (solid, gas) | No data available | |||||

High / low flammability or explosive limits | No data available | |||||

Vapor pressure | 0.0±0.5 mmHg at 25°C | |||||

Vapor density | No data available | |||||

Density / relative density | 1.1±0.1 g/cm3 | |||||

Water solubility | .; Stable. Combustible. Incompatible with strong oxidizing agents.Indofine[CS-674] | |||||

Partition coefficient of n-octanol / water | Log POW:3.36 | |||||

Air distribution coefficient of n-octanol | Log Kow used: 3.47 (exp database)

Log Kaw used: -2.896 (HenryWin est)

Log Koa (KOAWIN v1.10 estimate): 6.366

Log Koa (experimental database): None/ | |||||

Spontaneous combustion temperature | No data available | |||||

decomposition temperature | No data available | |||||

viscosity | No data available | |||||

Explosion characteristics | No data available | |||||

Oxidizing | No data available | |||||

Estimation of hydrosol from fragments | WatSol(v1.01est)=22.606mg/L | |||||

Henry's law constant (25 ℃) | Bond Method : 3.11E-005 atm-m3/mole

Group Method: 3.01E-004 atm-m3/mole

Henrys LC [VP/WSol estimate using EPI values]: 7.324E-006 atm-m3/mole/ | |||||

9.2 other safety information | ||||||

No data available | ||||||

Part 10: stability and reactivity | ||||||

10.1 stability | ||||||

No data available | ||||||

10.2 hazardous reactions | ||||||

No data available | ||||||

10.3 conditions to avoid | ||||||

No data available | ||||||

10.4 prohibited substances | ||||||

Strong oxidant | ||||||

10.5 hazardous decomposition products | ||||||

No data available | ||||||

Part 11: toxicological information | ||||||

11.1 toxicological impact information | ||||||

toxicity | ||||||

No data available | ||||||

Skin corrosion / irritation | ||||||

No data available | ||||||

Serious eye injury / eye irritation | ||||||

No data available | ||||||

Respiratory or skin allergies | ||||||

No data available | ||||||

Germ cell mutagenicity | ||||||

No data available | ||||||

carcinogenicity | ||||||

No data available | ||||||

Reproductive toxicity | ||||||

No data available | ||||||

Specific target organ systemic toxicity (one exposure) | ||||||

No data available | ||||||

Specific target organ systemic toxicity (repeated exposure) | ||||||

No data available | ||||||

Inhalation hazard | ||||||

No data available | ||||||

Additional description | ||||||

No data available | ||||||

Part 12: ecological hazard information | ||||||

12.1 ecotoxicity | ||||||

No data available | ||||||

12.2 durability and degradability | ||||||

No data available | ||||||

12.3 possibility of rapid biodegradation | ||||||

Biowin1 (Linear Model) : 0.8041

Biowin2 (Non-Linear Model) : 0.9530 | ||||||

12.4 expert investigation of biodegradation results | ||||||

Biowin3 (Ultimate Survey Model): 2.7914 (weeks )

Biowin4 (Primary Survey Model) : 3.6966 (days-weeks ) | ||||||

12.5 possibility of MITI biodegradation | ||||||

Biowin5 (MITI Linear Model) : 0.4947

Biowin6 (MITI Non-Linear Model): 0.5354 | ||||||

12.6 possibility of anaerobic biodegradation | ||||||

Biowin7 (Anaerobic Linear Model): 0.2665 | ||||||

12.7 ready made biodegradability prediction | ||||||

NO | ||||||

12.8 hydrocarbon biodegradation | ||||||

Structure incompatible with current estimation method!/ | ||||||

12.9 adsorption of aerosols | ||||||

Vapor pressure (liquid/subcooled): 1.02 Pa (0.00767 mm Hg)

Log Koa (Koawin est ): 6.366

Kp (particle/gas partition coef. (m3/ug)):

Mackay model : 2.93E-006

Octanol/air (Koa) model: 5.7E-007

Fraction sorbed to airborne particulates (phi):

Junge-Pankow model : 0.000106

Mackay model : 0.000235

Octanol/air (Koa) model: 4.56E-005 / | ||||||

12.10 hydroxyl radical reaction | ||||||

OVERALL OH Rate Constant = 200.8296 E-12 cm3/molecule-sec

Half-Life = 0.053 Days (12-hr day; 1.5E6 OH/cm3)

Half-Life = 0.639 Hrs | ||||||

12.11 ozone reaction | ||||||

No Ozone Reaction Estimation | ||||||

12.12 fraction of particulate adsorption in air (PHI) | ||||||

0.00017 (Junge,Mackay)

Note: the sorbed fraction may be resistant to atmospheric oxidation/ | ||||||

12.13 soil adsorption coefficient | ||||||

Koc : 1308

Log Koc: 3.117 / | ||||||

12.14 alkali / acid catalyzed hydrolysis (25 ℃) | ||||||

Rate constants can NOT be estimated for this structure!/ | ||||||

12.15 estimating bioaccumulation using log Kow | ||||||

Log BCF from regression-based method = 1.972 (BCF = 93.73)

log Kow used: 3.47 (expkow database)/ | ||||||

12.16 removal in wastewater treatment | ||||||

Total removal: 22.53 percent

Total biodegradation: 0.16 percent

Total sludge adsorption: 11.49 percent

Total to Air: 10.88 percent

(using 10000 hr Bio P,A,S)/ | ||||||

12.17 three level fugacity model | ||||||

Mass Amount Half-Life Emissions

(percent) (hr) (kg/hr)

Air 0.201 1.28 1000

Water 19 360 1000

Soil 80 720 1000

Sediment 0.793 3.24e+003 0

Persistence Time: 411 hr// | ||||||

12.18 mobility in soil | ||||||

No data available | ||||||

12.19 evaluation of PBT and vpvb results | ||||||

No data available | ||||||

12.20 other harmful effects on the environment | ||||||

No data available | ||||||

Part 13: waste disposal | ||||||

13.1 waste treatment | ||||||

Product method | ||||||

None | ||||||

Contaminated packaging | ||||||

None | ||||||

Part 14: Transport Information | ||||||

14.1 UN number | ||||||

ADR/RID: | None | |||||

IMDG: | None | |||||

IATA-DGR: | None | |||||

14.2 UN proper shipping name | ||||||

ADR/RID: | None | |||||

IMDG: | None | |||||

IATA-DGR: | None | |||||

14.3 Transport hazard class(es) | ||||||

ADR/RID: | None | |||||

IMDG: | None | |||||

IATA-DGR: | None | |||||

14.4 Packaging group | ||||||

ADR/RID : | None | |||||

IM0DG: | None | |||||

IATA-DGR: | None | |||||

14.5 Environmental hazards | ||||||

None | ||||||

14.6 Special precautions for user | ||||||

None | ||||||

14.7 Incompatible materials | ||||||

None | ||||||

Part 15: information on laws and regulations | ||||||

15.1 rules / regulations specific to the safety, health and environment of the substance or mixture | ||||||

Applicable laws and regulations | ||||||

None | ||||||

Other provisions | ||||||

None | ||||||

Part 16: other supplementary information | ||||||

Other information Copyright:FOUNT BEIJING BIO TECH CO.,LTD. Unlimited paper copies are permitted, for internal use only. The above information is deemed to be correct, but does not contain all information. It is only used as a guide. The information in this document is based on what we know at present and is applicable to this product in terms of correct safety tips. This information does not guarantee the nature of this product. Biofount and its affiliates shall not be liable for any damage caused by any operation or contact with the above products. For further terms of use, see the reverse side of the invoice or packing slip. For further terms and conditions of sale, please refer to http://www.bio-foundation.com/ or the back of the invoice or packing list. The logo on the header or footer of this document may temporarily not visually match the product purchased as we are transitioning our brand. However, all information about the products in this article remains unchanged and is consistent with the products ordered. For more information, please contact: sales@bio-foundation.com | ||||||

- 相关产品

-

< >

- 推荐产品

-

< >

- 最新产品

-

< >

新闻

怎么做细胞爬片免疫组化染色实验

细胞爬片免疫组化染色,是通过细胞爬片是让玻片浸在细胞培养基内,细胞在玻片上生长,主要用于组织学,免疫组织化学...

2020/7/20 22:04:33

提取病毒RNA的实验方法

提取病毒RNA方法分别有:异硫氰酸胍的提取病毒RNA方法、TRIzol LS提取法、Trizol法提取法等等...

2020/7/22 20:29:26

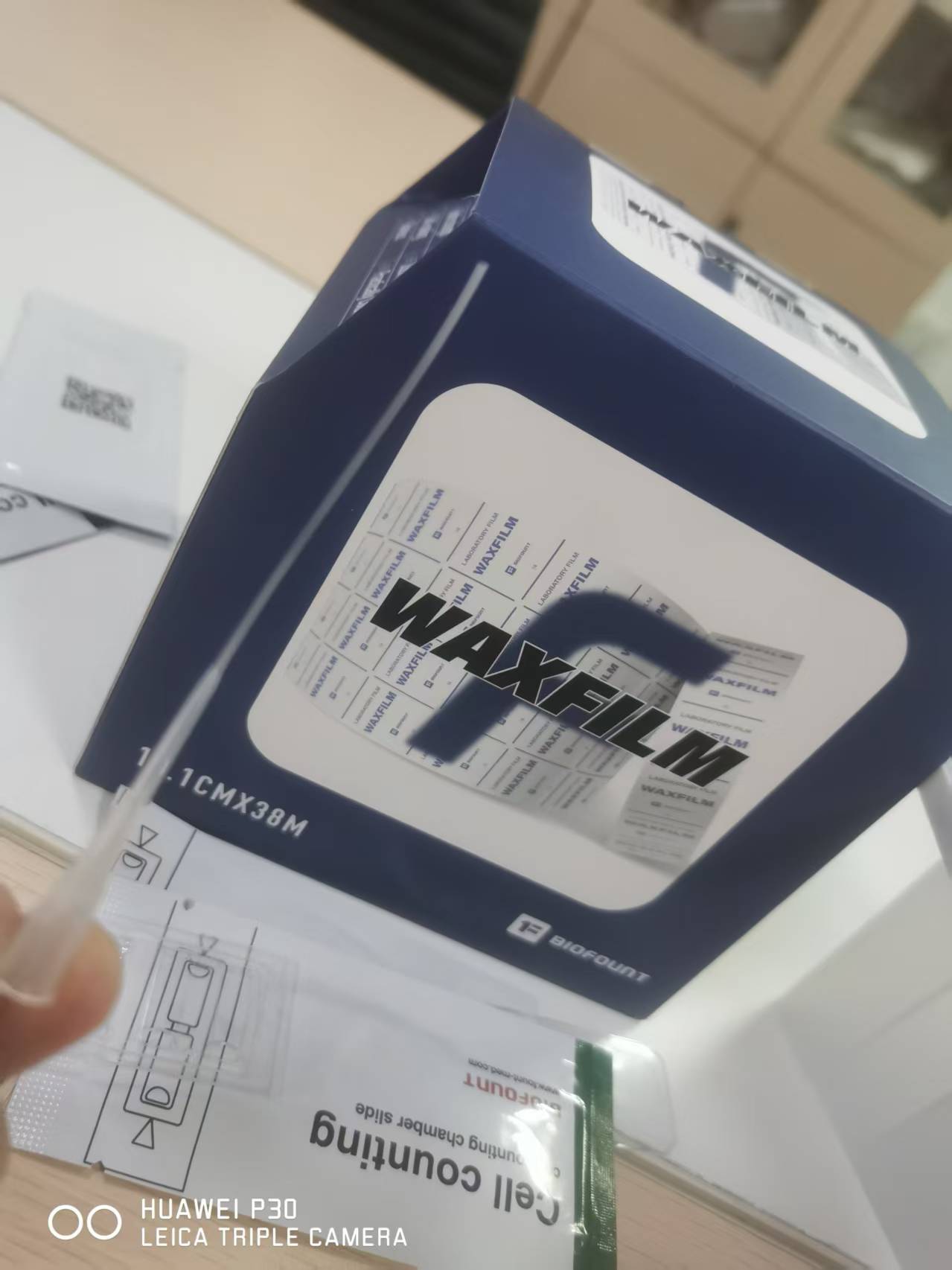

Waxfilm 实验室封口膜:技术与国际市场的双重突破

在实验室耗材领域,封口膜是保障实验准确性与稳定性的关键产品之一。近年来,Waxfilm?实验室封口膜凭借其卓...

2025/5/13 13:03:40

Waxfilm实验室封口膜的5大突破

Waxfilm实验室封口膜作为生物功能膜领域的国产技术突破和品牌突破,是生物领域中国技术发展的缩影。

2025/5/6 17:02:07

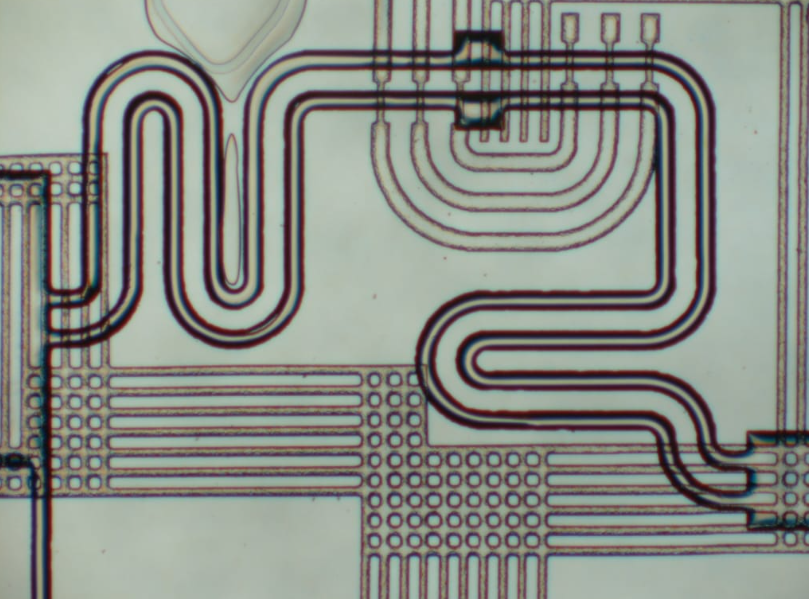

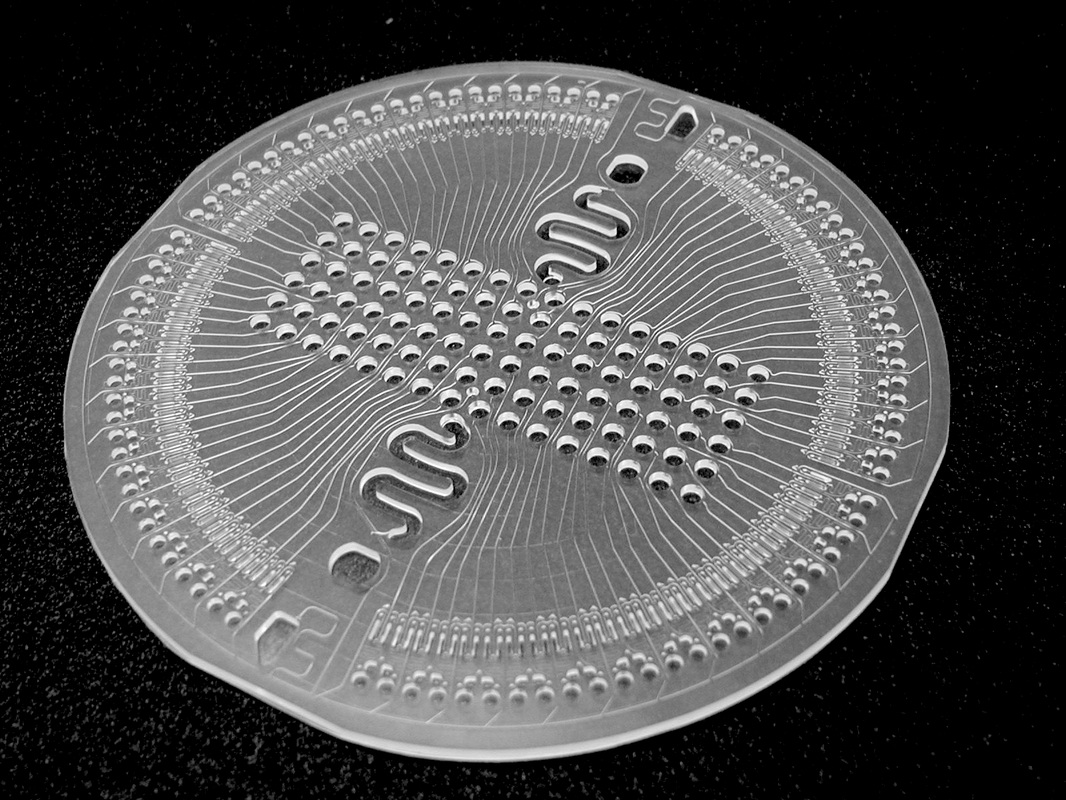

各种微流控芯片键合方法的优缺点

微流控芯片键合:目前主要有激光焊接、热压键合、胶键合、超音波焊接,每种方法都有各自的优缺点。本文主要介绍聚酯...

2023/7/28 10:43:09

新一代微流控键合解决方案

微流控键合解决方案:微流控芯片制造的一个重要环节,也是最容易被忽视的--芯片键合。其中一个重要因素是:微流控...

2023/7/27 12:44:28

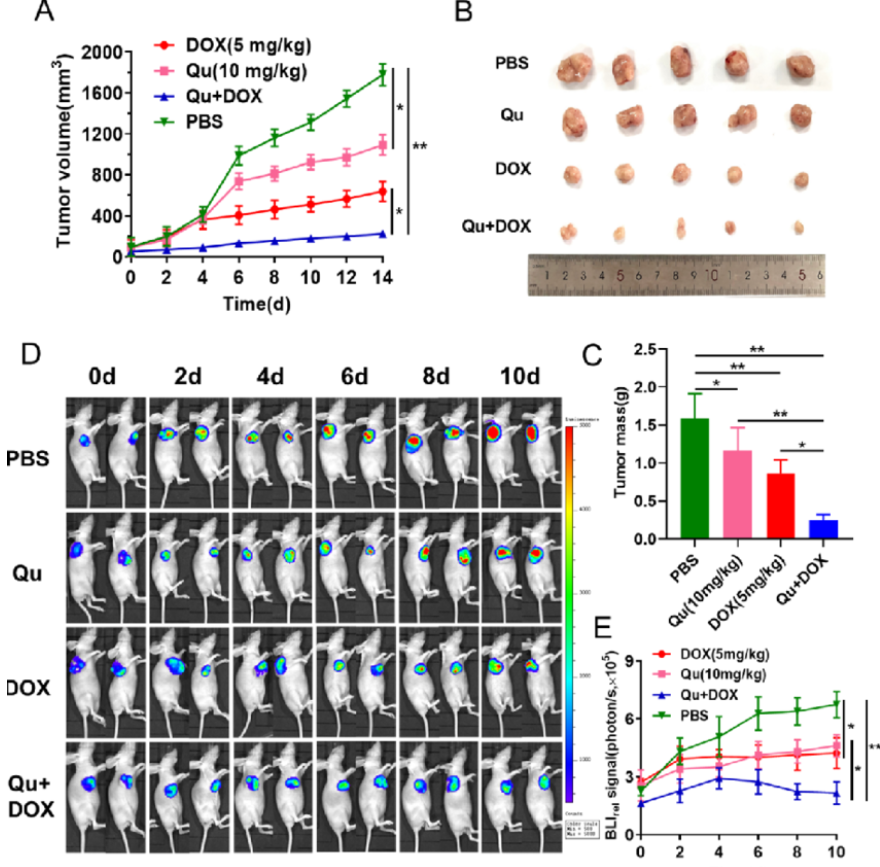

荧光素钾盐使用说明

D-荧光素钾盐(K+)设计用于体外和体内生物发光测定。D-荧光素的质量和纯度对于获得良好和可重复的结果至关重...

2023/7/20 11:05:11

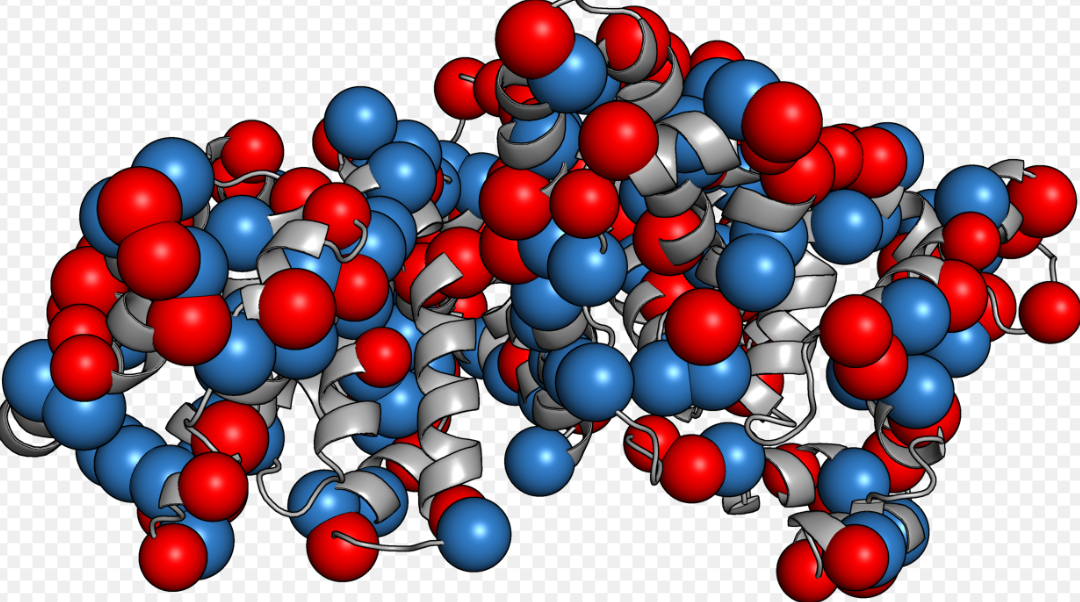

如何选BSA(牛血清白蛋白)

如何选BSA(牛血清白蛋白):牛血清白蛋白(BSA)有多种形式,如何选择适合自己的牛血清白蛋白(BSA)是一...

2023/2/14 13:09:18

牛血清白蛋白(BSA)常见问题

牛血清白蛋白(BSA)常见问题:牛血清白蛋白(BSA)在实验室中是通用的,可用于蛋白质印迹、细胞组织培养、P...

2022/10/19 9:39:51

pubmed使用方法(技巧)

pubmed使用方法(技巧):PubMed是一个关于医学问题的学术文章和书籍的数据库。因为它是一份学术期刊,...

2022/10/18 18:06:07

购物车

购物车